Yeah, it’s been a while. Maybe no one reads this. But that’s OK. My life has been crazy, because these are crazy times. Please read on.

Ok, so I said I won’t talk about politics on this site. It still holds true, I won’t. I won’t tell you how to vote, or what to believe. What I can and will do, however, is point out gross injustice that directly touches people I give a shit about; most of my extended reader base has no idea about what is happening in Indian Country. However, maybe you are curious. If so, read on. If not, maybe skip this post until I get back into topics that fit into your comfort zone.

Over the past month or two, two nieces of mine have been directly threatened with physical violence through no fault of their own. I guess I must define “physical violence.” By this, I mean armed men threatening them directly with death, injury, or legal sanction. Hopefully, that is clear.

Women, fucking women, unarmed, in one case with an infant in close proximity.

In the first case, as I related earlier on my paywall site, a girl in my community had people show up at her house because they were pursuing a DoorDash driver who happened to be a Hispanic lady. By the way, you can’t work for DoorDash unless you submit proof that you are legally authorized to work in the US. The DoorDash lady ran into my thožaŋ’s (niece’s) house in a panic; a tense, armed standoff ensued. My niece prevailed in that case; the poor middle-aged lady was not detained.

I’ll get into the second case in a bit. But first, I’ll talk a little about why I was just in Mnísota, in Dakhóta country.

A man who helped me, who made a difference in my life, passed away at the age of 44. When I heard the news, I did not question whether I should be there for the family. No. I threw my clothes into a trash bag, made arrangements for my cats (it’s a thing), and loaded the truck with my dog. Thirteen hours later, I was chilling in my hotel in Inver Grove, close by the Twin Cities.

Early that same day, I cruised through the places where some people had recently been shot in the street, and many arrested. Minneapolis has a seriously weird vibe. I’ve felt that before in other places, not in the US. There is a palpable feeling of anger and danger there; you can see it in how people walk; their heads on a swivel. It’s as if the whole city is just waiting for something to happen. You don’t ever want to feel that, and I didn’t think I ever would, again. Not in the US! Oh, ok, here we go again, I thought.

I drove through the city because I wanted to “wipe down,” to attend a sweat lodge. The man who conducted the lodge is a blood-related cousin; he is a gentle man, a good man and father. He expressed a fear to me that he or his family would be detained, unjustly. I’ve learned that this is not paranoia or misplaced fear; it’s a real thing amongst American Indians in Minneapolis.

Driving While Brown; shorthand for being fucked with by…people of unknown origin, who operate with no identifying badges, faces covered, and apparently, a license to detain and kill.

If you think I may be unhappy about this, you would be correct.

As an aside, the trope about women being “the weaker sex” is complete bullshit. Throughout history, the record is replete with women who have spoken courage into the men; who have led and died for what they strongly believe, and what they wish to protect.

The reason I am writing this piece is a direct result of a conversation I held with a woman I respect, who called me out for not wanting to publically express my displeasure regarding these gross violations of the rights of my people. I wished to be cautious, to not draw the attention of the bad people who are shitting on the US Constitution, and the safety of my Dakhóta family in the West.

She said, in essence, that I was being a pussy, if you’ll excuse my French. She cited her situation where she refuses to live in fear of being fired; she teaches history and refuses to adjust her curriculum to please the gods of reverse PC.

Her words singed my ears a bit; I thought about it, and decided to write. I have a platform, albeit small. What is my excuse? There is none.

This morning, having returned from Minnesota yesterday at 0500, I sat down and composed this piece. Maybe I piss some of you off: it’s OK. The truth hurts. Here is wówičakhe, truth. A Dakhóta man must never shy away from truth, so I will speak it this morning.

Agents of the federal government directly threatened two of my relatives for no good reason. This is truth. You can watch one incident in the link above.

I’ll talk about the second incident below, after having described how I came to learn of it.

So, to back up in the timeline a bit, I sweated with my cousin and others from the community, and I returned to my hotel to clean up for the memorial. I passed through a city under siege on the way; I didn’t enjoy it, and I know, in my balls and guts, what it is like to be under direct threat from militias who come in the night. My anger built.

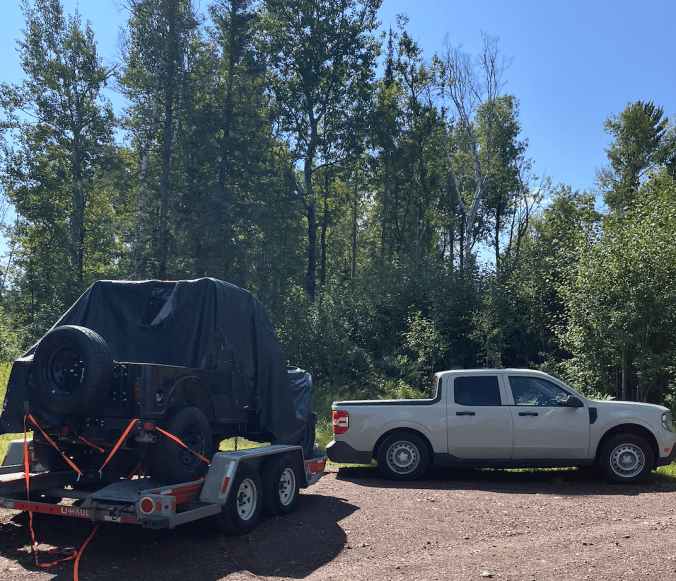

After washing, I traveled to the Rez with my faithful companion, the crazed Aussie cattle dog.

I arrived at the site of my home lodge, the Black Horse Camp. From there, I won’t describe the sequence of events; suffice to say our departed was honored and returned to the earth in a good way.

Hence the pic of the cigarettes; a bowl laid upon each table at the memorial. It is the only picture I took; cell phone use is not tolerated during ceremony, nor should it be. Tobacco, čhaŋdí, is one of the sacred medicines. Therefore, it was made available for the people.

Laughter is also a medicine; there was a lot of it. Kids ran about and played; it gladdened my heart to see that. The people were fed, the ladies made totally delicious buffalo meat fry bread one evening! Lord, how I ate. If you ever come to a Dakhóta thing, you will eat. Period.

On the penultimate night, I spoke to another niece, a good-looking and kind Ojibwe girl I like a great deal. She’s smart as a tack and has done much for my community.

I heard she had been threatened. So, I asked her what happened. She told me.

I guess she was driving to work, right? Just another day during this weird siege of her city.

A note about my niece: she looks Capitol “I” American Indian. I guess that’s good enough for a Kavanaugh Stop; if you don’t know what that means, you can read my link.

Well, she picked up a “tail,” or a vehicle that surrepitiously followed her. It was a white Jeep. Locals have gotten wise to ominous black Suburbans (as an aside, wtf is up with these people cosplaying supervillains? But, I digress). When she parked at her place of employment, the white Jeep boxed her into the parking spot and THEN the Suburbans shot to either side of her car.

She freaked out; she was carpooling and knew she was about to be in trouble. It was just another day, as she commuted to work.

I’d like to point out that BOTH of my nieces hadn’t been “poking the bear” (although that is perfectly legal under the FIRST AMENDMENT OF THE FUCKING US CONSTITUTION). No, they were just going about their lives.

And there she was, fumbling with her phone, rolling down her window (she didn’t want it shattered, which is a thing), and…

Having a goddamn loaded weapon jammed in her face.

The weapon promised lead and copper, at high velocity, to violate her head and leave her life to trickle upon the floor of her car, or splattered across the interior.

Yes, that is graphic. No, I don’t care. This could have been the reality if she’d twitched just a little bit; whoever the fuck it was could have drilled her, with zero consequence, and for no reason.

This, at least, has been made overly clear. An agent of the state, with his face covered and in plainclothes, could have robbed her of her life, with no questions asked. And this time, there wouldn’t have been any witnesses present. There was a security cam, which she saw footage from later on, that was all.

In the moment, all there was were mortally scared brown people who hadn’t done Jack Shit. For some reason, she wasn’t detained; perhaps there wasn’t room in the Black Ravens. But they sure as hell nabbed the people in her car, with violence. She told me most didn’t wear any sort of uniform. She did see one dude in a greenish outfit with a “Police” patch, but that was it. All of their faces were covered; it could have been a mob hit for all that she knew.

Shitting herself, the attackers, the creeps, left a pretty Ojibwe girl, 100 percent born and raised in the USA, a card-carrying member of a sovereign Native American nation, trembling in their wake.

Guys, this is the definition of tyranny. If you can’t see that, if you can somehow justify that, I don’t know what to say.

Is this what we are? In a place where it’s totally cool to round up and brutalize people who vary just slightly from an imagined American ideal? In thrall to a murderous ideology that should have died in the ashes of the Second World War, or the US Civil War?

My people fought and fucking died to defeat these ideas, and many of your ancestors did the same.

This, guys, is my hill.

In everybody’s life, there is a hill. A place that you will defend against all comers. Many shy away from the hill, and they disgrace themselves and their relatives. The measure of a man, or a woman, is what they will do for those they love and care about. All of us will die one day; it is our common fate. You don’t get a choice; death is not optional.

Where the choice lies is how you die, and what legacy you leave behind.

I choose not to stand or be complicit with those who jam fucking loaded weapons into the faces of my relatives!

That’s how it is.

I have spoken wówíčakhe, the truth. It is all that I can do, and it is a symptom of the sickness in our land that I hesitated to do so earlier.

Let the chips fall where they may.